sheet metal drawing operation is used to make

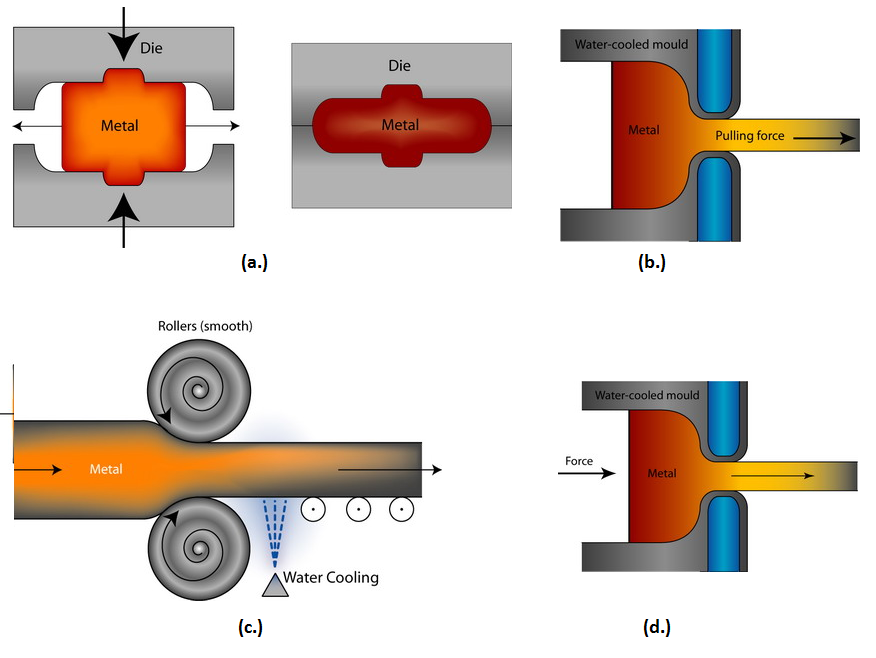

Forming process are particular manufacturing process which make use of suitable stresses like compression tension shear or combined stresses which cause plastic. Operation in which large sheet metal or plate metal parts are formed into curved sections by means of rolls Roll straightening nonflat sheets are straightened by passing them between a.

Cup-shaped objects utensils pressure vessels gas cylinders cans shells kitchen.

. As the metal is drawn pulled it. So the stamping press is making a reciprocating motion on stamping dies. Sheet Metal Drawing Operation Is Used To Make It Is Used To Cut Out The Width And Length Of The Expanded Graph With The Cutting Machine.

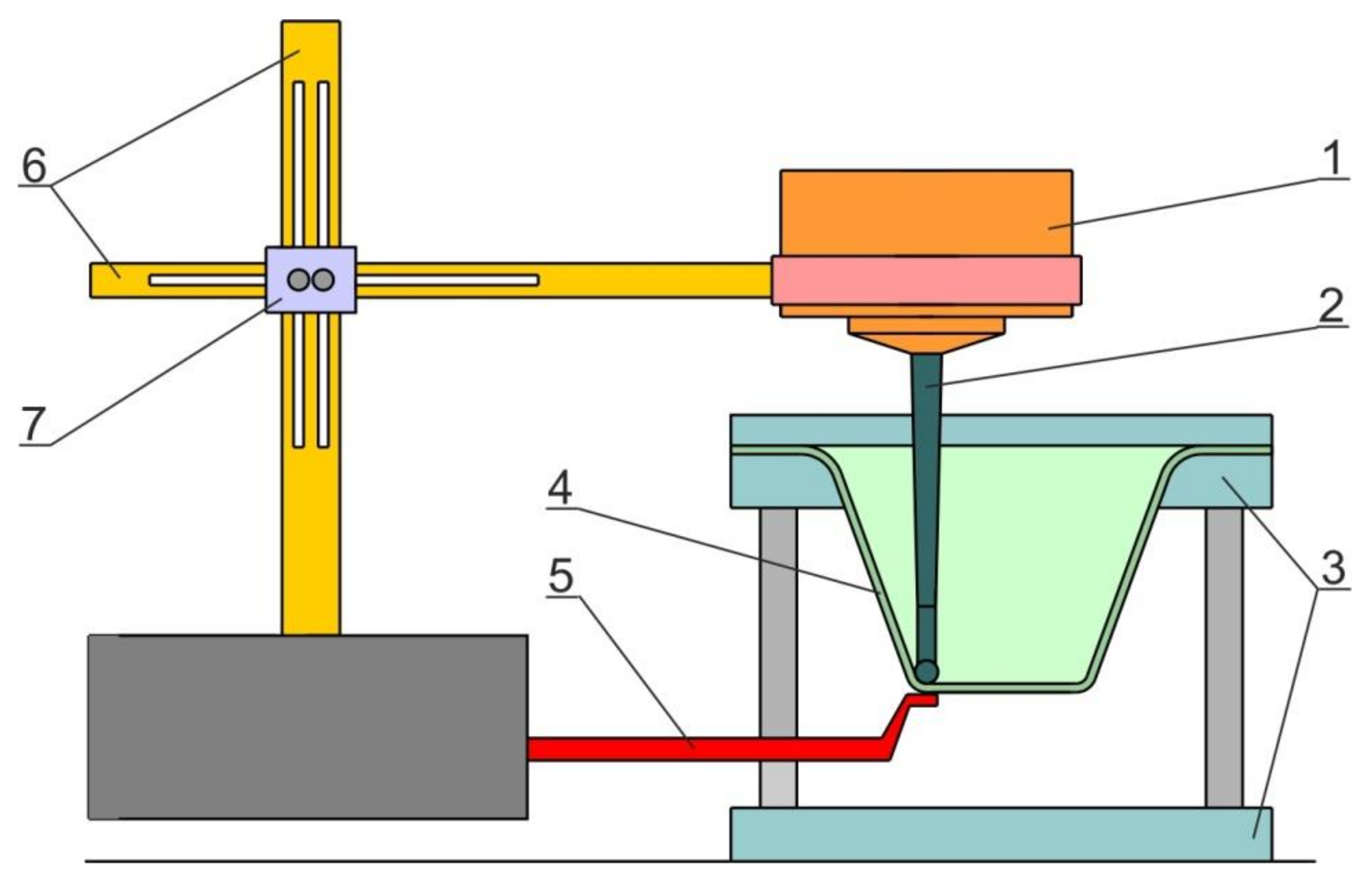

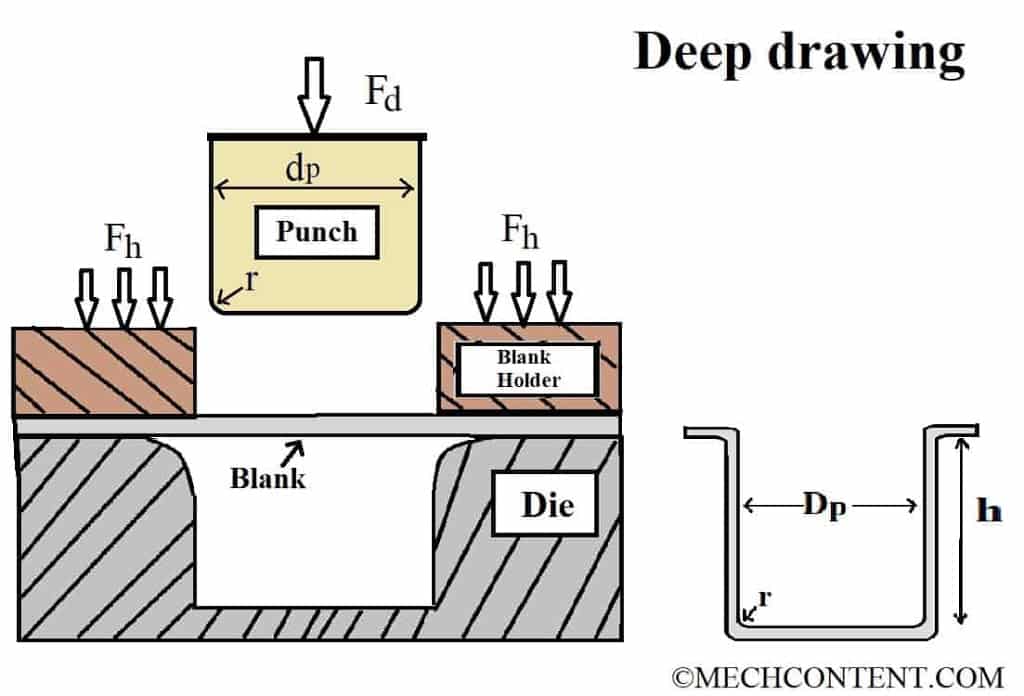

Detailed Solution Cup drawing or deep drawing is one of the widely used sheets metal forming operations. The die cavity matches the punch and is a little wider to. Drawing metal into the.

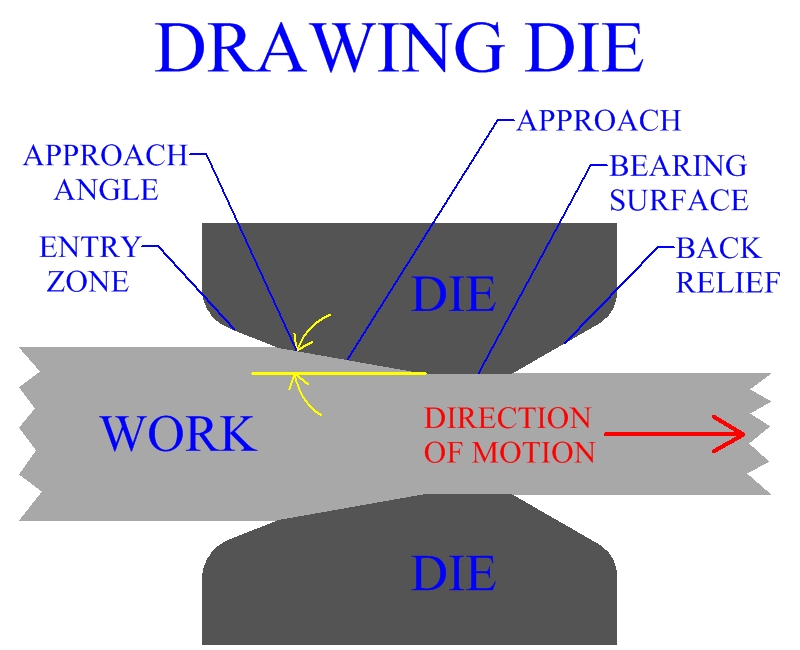

This is accomplished by forcing the work through a mold die of smaller cross sectional area than the work. Drawing is accomplished by placing a piece of sheet metal. Bending This step includes bending sheet metal for creating the metal components.

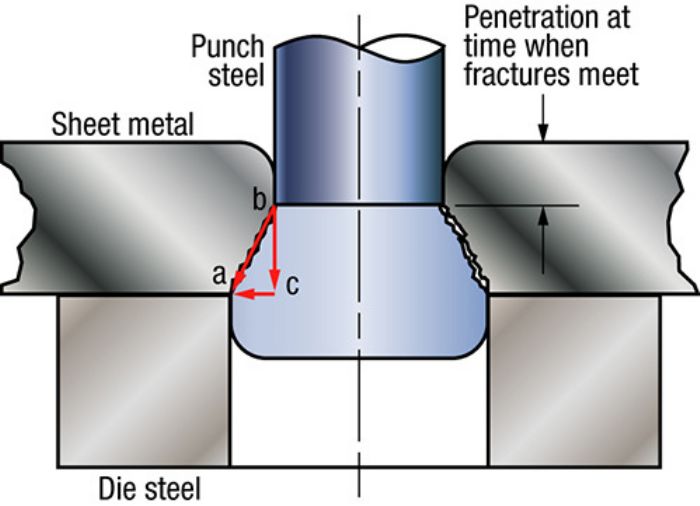

Sheet metal Drawing operation 2396 views Aug 23 2017 Drawing is a metalworking process which uses tensile forces to stretch metal or glass. Shearing Operations The Shearing operation is a cut in a straight line across a strip sheet or bar. The punch pushes the.

It leaves a lean edge on the piece of metal that is sheared or cut. The most used sheet metal fabrication process is the stampşng process. As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness.

Deep drawing is a metal forming operation in which the sheet metal is stretched into a desired shape by the mechanical action of a punch. Sheet metal drawing is a metal forming operation in which the metal blank is stretched into a desired shape by the mechanical action of a punch. This process is very similar to metal extrusion the difference being in the application of force.

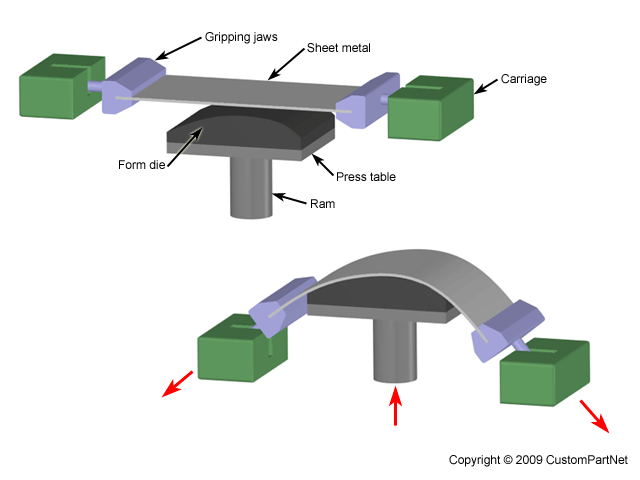

The punch pushes the sheet metal. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and. Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic.

Deep drawing of sheet metal is performed with a punch and die. And also they place virgin sheet metal on stamping dies. The following steps are involved in the process of sheet metal forming.

The common types of sheet metal operations are shearing blanking punching piercing trimming drawing embossing bending and squeezing operations. Repeated bending is also used for complex shapes. Press brakes are used to press the longer lengths of metal.

The punch is the desired shape of the base of the part once drawn. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity. Small lengths metals are bent with the help of the dies during the process.

The drawing process is a sheet metal operation to convert a flat blank of sheet metal into a hollow vessel without wrinkles and cracks and without trimming and in cold or. In the most basic explanation there is a stamping press and stamping die in these pieces of machinery. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

What Is The Basic Difference Between Deep Draw And Forming Operations In The Sheet Metal Process Quora

Metals Free Full Text Recent Developments And Trends In Sheet Metal Forming Html

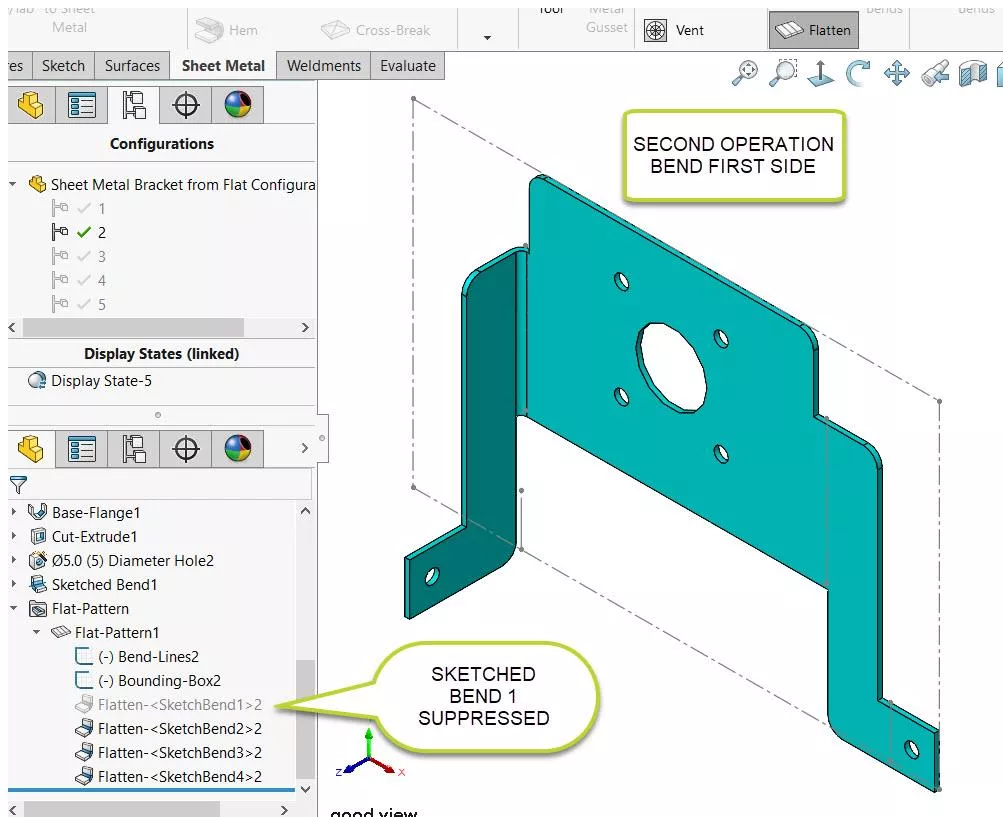

Solidworks Sheet Metal Tutorial Using Flat Pattern And Sketched Bend Goengineer

Metal Forming Machine Tools Part 1 Bulk Metal Engineering360

Bending Drawing Slitting Trimming Shaving Process Working Animation Metal Forming Operations Youtube

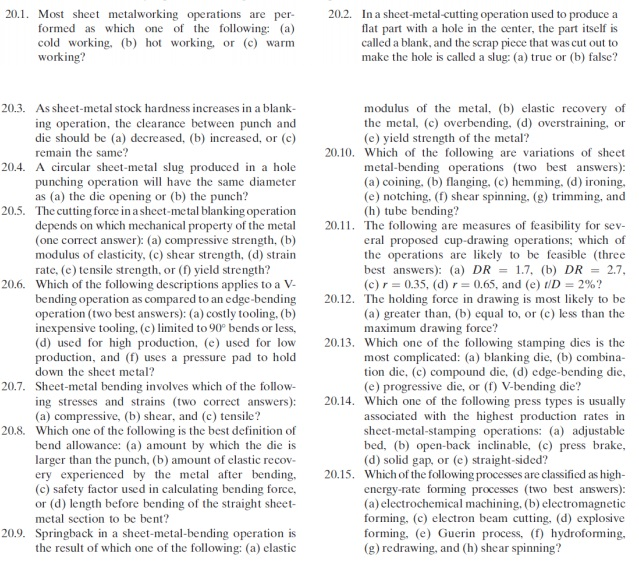

Die Basics 101 Fundamentals Of Drawing And Stretching

Deep Drawing Operation In Sheet Metal Smlease Design

Deep Drawing Process What Is It Formula Defects Calculation Applications Advantages With Pdf

Deep Drawing Operation In Sheet Metal Smlease Design

Virtual Lab Dayalbagh Educational Institute

Deep Drawing Operation In Sheet Metal Smlease Design

Understanding Horizontal Forces In Stamping Dies Metalforming Magazine Article

Types Of Drawing Operations In Sheet Metal Common Defects In Drawing Operation Youtube

Deep Drawing An Overview Sciencedirect Topics